in the processing of metals

aluminium for the maritime,

railway and construction industries

the highest standards in the industry

forward-looking technologies of metal processing

certified products

consulting, transport, installation

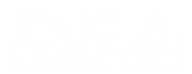

We specialise in processing black steel, stainless steel and aluminium. We work for the maritime, railway and construction industries. We manufacture metal elements and their components. We conduct welding works in the scope of steel load-bearing structures and steel structures, including in particular the railway industry. We always find the best solutions. We provide comprehensive services to our customers while maintaining international quality standards and applicable European standards.

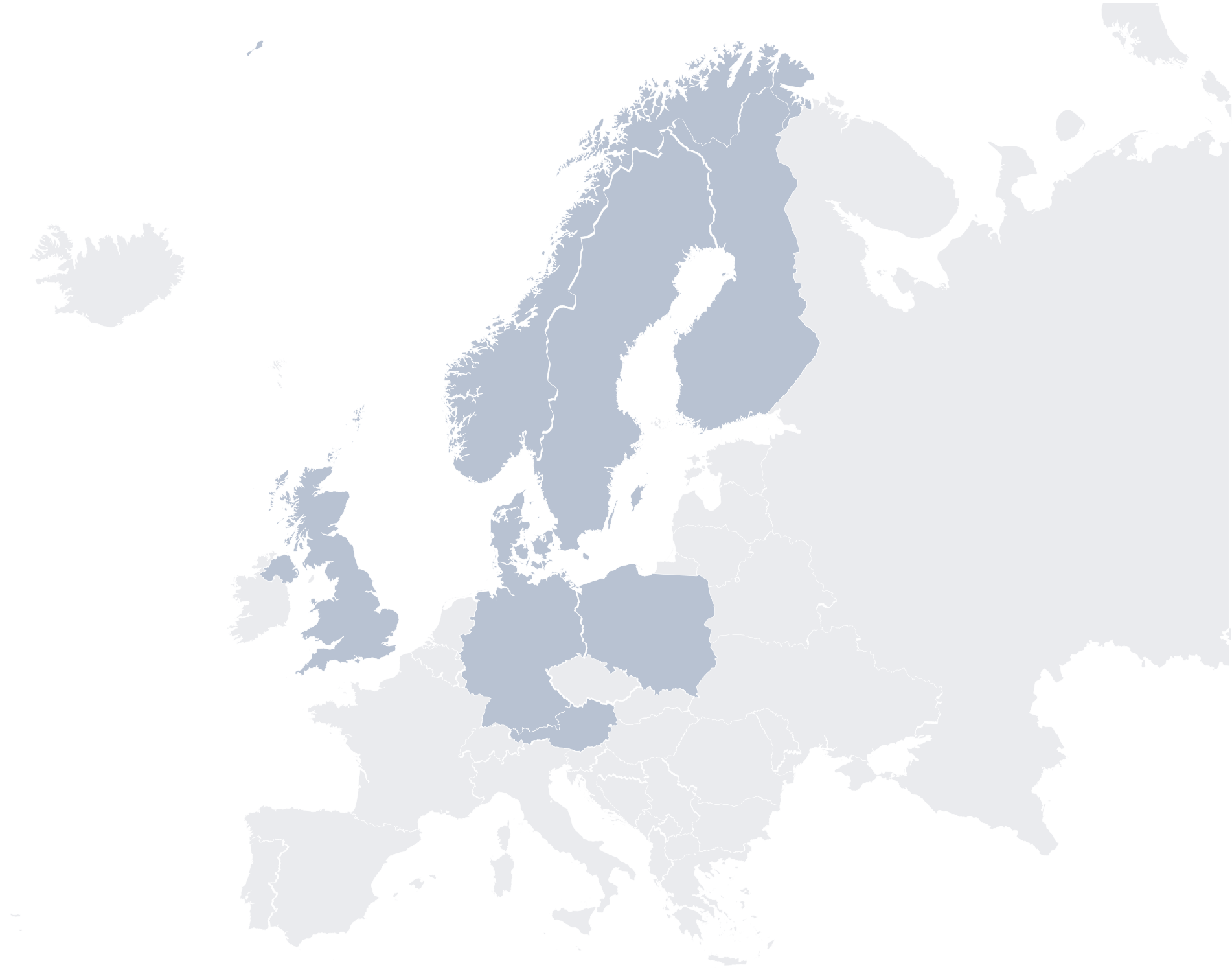

The use of the latest technologies, constant quality control and qualified personnel are our priority goals, and building long-term relations and increasing competitiveness in the method of metal processing are an incentive for us to continuous development. Our products can be found in many European countries, including: Poland, Germany, Great Britain, Denmark, Austria, Finland, Sweden and Norway.

OFFER

We are properly qualified to perform TIG, MIG and MAG welding, confirmed by certificates compliant with PN-EN ISO 3834-2, PN-EN 1090-2 standards. We are qualified to perform welding works in the scope of structural elements of CL 1 rail vehicles in accordance with the PN-EN ISO 15085 standard. We have a modern welding shop equipped with Siegmund 28 Professional welding tables. We make steel structures such as halls, carports and precise steel structures, such as: transport racks for transporting insulated glass and elements for industry, hoppers, supports for industry and elements of small architecture. We are VT1/VT2 certified for visual weld testing. We cooperate with an accredited laboratory in the scope of non-destructive testing of metal structures.

We have the latest technological solution currently available in the market for thermal and plasma cutting. We precisely cut large sheet metals of great thickness, manufacturing a product of the highest quality. Perfect cutting results are possible thanks to the Eckert PLASMA CUTTER. Both plasma cutting and the ventilation system enable high dynamics and precision in cutting sheet metals, pipes, profiles and materials with a thickness of 0.5 mm to 30 mm. Working area from 1500 mm to 3000 mm. We cut angles without deformation, flat bars, round and square bars.

We offer the following products:

- girder legs,

- poles legs,

- sheet metals of various shapes,

- handles for walls and tanks,

- other precision components.

Bending of pipes and profiles is performed on a mandrel pipe bender and a press brake with a pressure of 160 tonnes. We bend sheet metals up to 10 mm thick. We perform plane and spatial bending of sections and profiles. We make various types of moulds and bend pipes with diameters from Ø6 to Ø100.

Internal and external metal flanging is performed with the KSE 12/10 machine. Round blanks 70-1000 mm. Sheet metal 2 mm thick.

Types of coatings for finishing metal surfaces:

- hot dip galvanisation

The process of mechanical applying a zinc coating, resistant to steel. A zinc coating is formed on both sides of steel as well as on the inner and outer surfaces of the closed profiles. In the alloying process zinc adheres to steel between steel and zinc. It creates a mechanically tough, durable and impermeable coating that protects steel owing to the special electrochemical system. - powder coating

It consists in applying electrified particles (20-100 μm) of powder paint to the conductive surface. The deposited layer of powder remains on the surface of the painted detail due to electrostatic forces.

Basic advantages of powder coating:- no emission of solvents and thinners to the environment,

- almost 100% use of painting material (possibility of recovery of non-deposited powder particles),

- significant energy savings thanks to the possibility of using closed ventilation systems,

- the obtained coatings, thanks to their thickness (60-80 μm), perfectly mask the inaccuracies of mechanical processing,

- polishing

Finishing treatment aimed at obtaining the desired smoothness and gloss of the surface of the polished object. Polishing is usually performed with soft (felt) discs and abrasive materials (e.g. polishing pastes) or by electrochemical methods. Metal polishing is necessary to improve the appearance of metal products as well as to obtain surfaces with high quality parameters. - anodising

Surface treatment of metals by electrolytic production of an oxide layer. Anodising is mainly used for aluminium and its alloys, but can also be used for some types of steel, titanium and magnesium alloys. - satin finishing

Processing of stainless steel or metals prone to contamination. This leads to the maximum clean, whole, uniform and often shiny surface. - chrome plating

Covering metal items with a chrome coating. It is used to increase wear resistance, improve thermal properties or for decoration.

The successively expanded Machinery Park allows for fast and effective welding, cutting, turning, milling, bending, drilling and threading. Thanks to innovative machines, we are able to provide comprehensive services to our customers, introducing new products and extending the services provided.

Machinery park

Jantar 1500 × 3000 plasma cutter with CNC-ECS control

| Technical specification of the cutter Jantar | |

|---|---|

| Cutting width | 1500 mm |

| Basic working length | Any length up to 3000 mm |

| Cutting thickness | up to 30 mm |

| Cutting quality | PN-EN ISO 9013 |

| Positioning accuracy | PN-EN 28206 |

Welding shop

Hydraulic guillotine QC 12 6/3200

| Technical specification of the guillotine QC 12 6/3200 | |

|---|---|

| Max. width of the cut sheet metal | 3200 mm |

| Max. thickness of the cut sheet metal | 8 mm |

| Buffer shift | 20-800 mm |

Mandrel bender

| Technical specification of the bender HTGR 63NC/4000 | |

|---|---|

| Max. dimension | Ø 63 x 4 mm |

| Max. bending radius | 350 |

| Min. bending radius | Depending on the pipe diameter |

| Max. bending | 190° |

| Max. distance from the mandrel | 4000 |

Brake press 3200/160 e200

| Technical specification of the press 3200/160E200 | |

|---|---|

| Pressing force | 160 tonnes |

| Max. Element length | 3200 mm |

| Distance between columns | 2650 mm |

| Max. Opening height | 415 mm |

Boschert cutter

Geka bendicrop 5011

Operations performed:

- Punching holes up to Ø 50 mm

- Rectangular punching die

- Cutting flat bars without deformation

- Cutting angles, round and square bars

- Flat bar bending

Cutting angles without material or bar losses. Material clamping guide. Shearing of angles without material loss. A wide range of holes for round and square bars.

Flat bar cutting station.

Cutting flat bars. Cutting the angle arms at 45º. Material clamping guide. Guide table for cutting flat bars. Adjustable clearance between the knives. Electric buffer. Flat bar cutting system without deformation.

Punching station.

Rectangular punching die with a table. This station can also be used for both pipe and triangular punching die.

Bandsaw

Contact

Borzym 53

74-100 Gryfino

+48 91 416 17 00

+48 91 416 17 77

biuro@dea-metalltechnik.com

REGON 321298749

KRS 0000443768